HAKO

HAKO is a fully automated countertop bubble tea machine geared towards businesses and office spaces. It aims to offer quality and accessible beverages to all the boba lovers out there.

Length:

15 months (Ongoing)

Tools:

Onshape; 3D printing; Electronics

Skills:

Rapid Prototyping; User Testing; Product Design

Chief Industrial Designer; My responsibilities include designing the form factors, user experience, conduct user testing, integration with the engineering model

My Role:

Team:

Kennedy Liu (Engineer) Cole Maisonpierre (PM)

Context

Bubble tea: A reason to innovate

Bubble tea, originated from Taiwan, has gained immense popularity in the U.S. among young adults – it's a way for different cultures to connect and share something unique and enjoyable

A Complicated Process

Making bubble tea by hand is a complicated and time consuming process. That’s why it’s 80% more expensive than coffee. A standard bubble tea requires:

Single-Use Plastic Pollution

In addition, the American bubble tea trade produces roughly 1500 cubic meters of solid landfill plastic every year due to the single use plastic packaging.

How do we automate the bubble tea making process to make it more accessible and eco-friendly while preserving its quality and fun?

Our Customers

Our End User

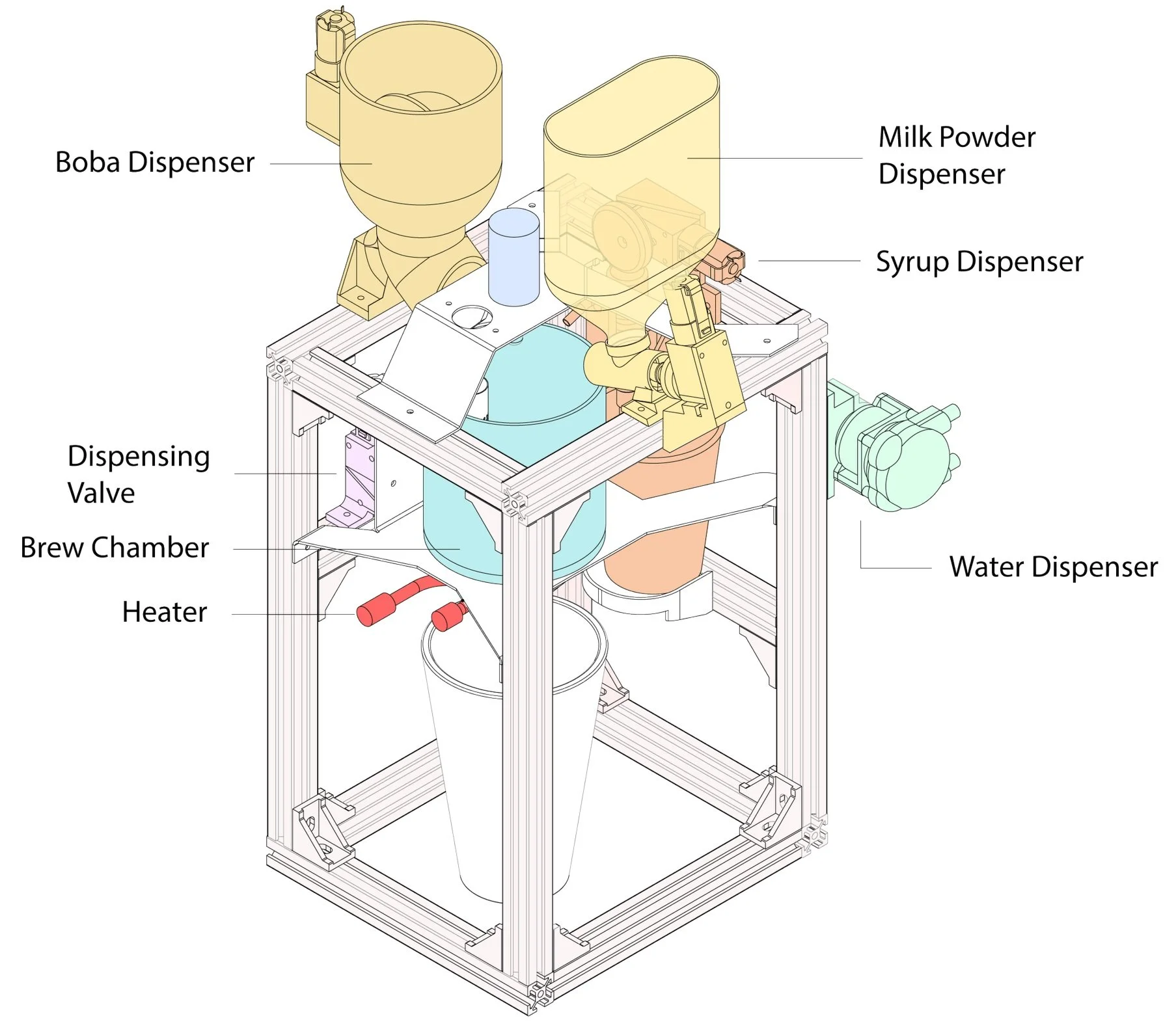

Engineering Prototype

The goal of this engineering model is to create and test the feasibility and challenges in various dispensing and heating subsystems

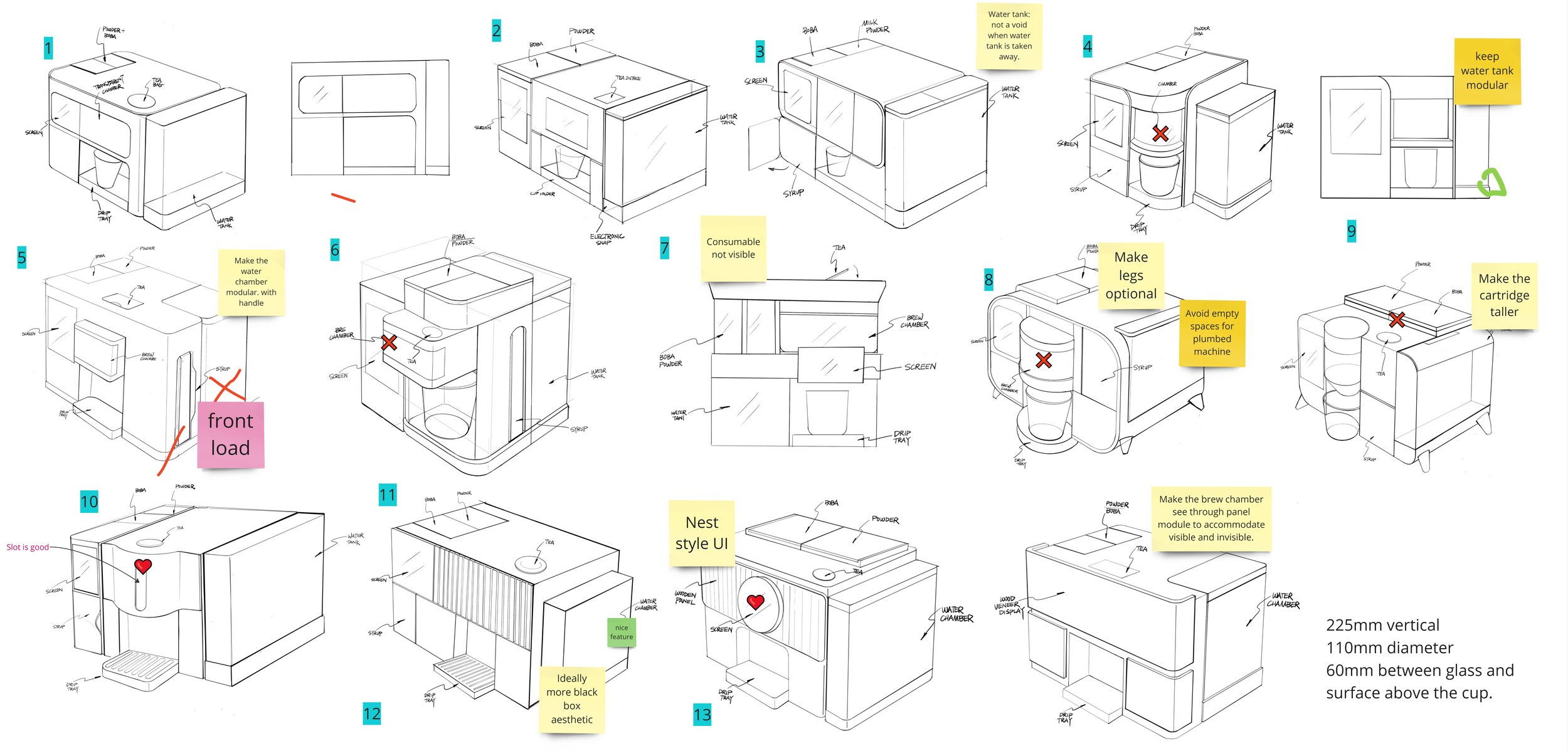

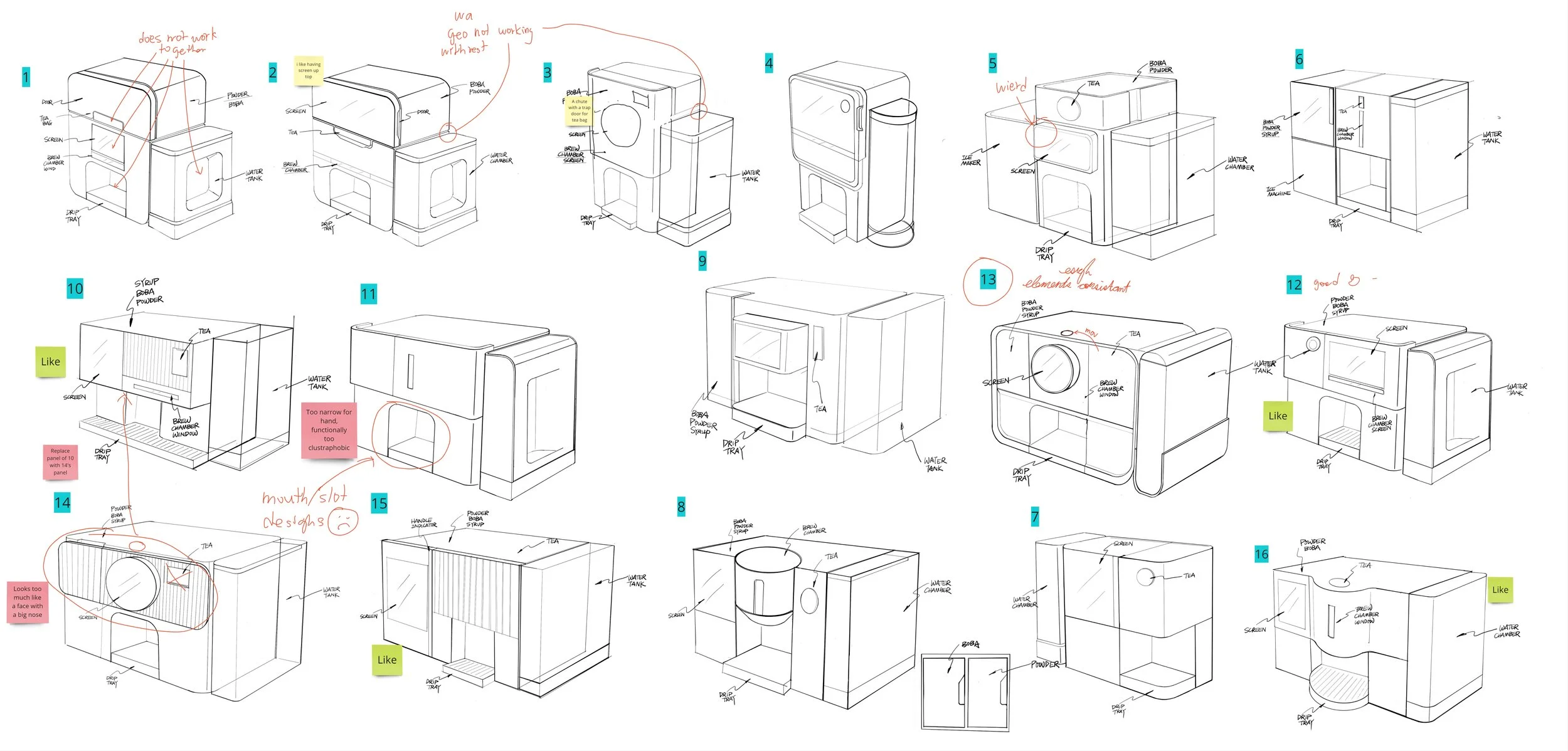

Ideation

Initial Machine Flow Brainstorm

Prototype: Horizontal Architecture

The horizontal machine architecture stores raw materials (Boba, Milk Powder, Syrup) on the left compartment with brew chamber and screen on the right.

Drip Tray

Cup Holder

Replace Cartridge

Water Tank

Vertical Architecture

The vertical machine architecture places the dispensing system on top of the brew chamber. It is much more technically feasible. However, it cannot fit under standard kitchen cabinets.

Tea Bag Insert

Screen

Drip Tray

Consumable Cartridge

User Testing

We designed a set of UI for the vertical and horizontal design that simulated the step-by-step operation/maintenance of the device.

User Feedback

Final Design

HAKO aims to expand the bubble tea market by bringing quality bubble tea production into new spaces

Step 1:

Place Your Cup

Place the HAKO cup at the cup bay to start the drink selection process

Step 2:

Customize Your Drink

Select your desired sugar and ice level and start the brewing process

Step 3:

The machine will display the drink progress with a QR code to check drink status remotely

Wait 5 Minutes

Step 5:

A message will be sent to you once the drink is finished. Walk to the machine and get your drink.

Drink Finished!

Easy & Efficient Maintenance

With automation at every stage, Hako streamlines its daily maintenance cycle, requiring minimal user intervention.

Convenient Drip Tray

HAKO’s drip tray holds around 500 ml, intended for collecting accidental drips and spills. Its size is quick and easy to maintain and clean.

Self-Cleaning Cycle

HAKO self rinses its system 15 minutes after its latest use. The waste water is directed to the waste water tank which will be disposed at the end of the day.

End-Of-The-Day Upkeep

Staff of the space empties the waste water tank, clears the drip tray and replenishes the dry consumables.

Deep Clean

HAKO allows for simple methods of deep clean by simply placing the HAKO cleaning pod into the machine.

HAKO Reusable Cup

HAKO is taking a pioneering step towards eco-friendly beverage dispensing. Its innovative design utilizes reusable HAKO cups, significantly reducing the reliance on single-use plastics common in traditional bubble tea shops.