Briota IoSPRO

An impulse oscillometor for asthma diagnosis used in rural India

Team Project

2023 Fall, 5 weeks

Design For Scale (MIT D-Lab)

Info:

Kai Zhang (Designer)

Kayra Berk Ilkbahar (Engineer)

Emiko M Pope

Team:

Skills:

Industrial Design; User Testing; Prototyping

Tools:

Solidworks; Illustrator; 3D Printing; Arduino

Role:

Communication with our client Briota; create concept sketches; prototypes; and user testing

Impulse Oscillometry is a form of non-invasive diagnosis method for asthma that uses sound waves to measure respiratory mechanics

Challenges In Asthma Diagnosis In Underdeveloped Areas

User Persona

Scope Of Work

Briota provided us the internal air manifold for the device. We are tasked with designing a

User Flow

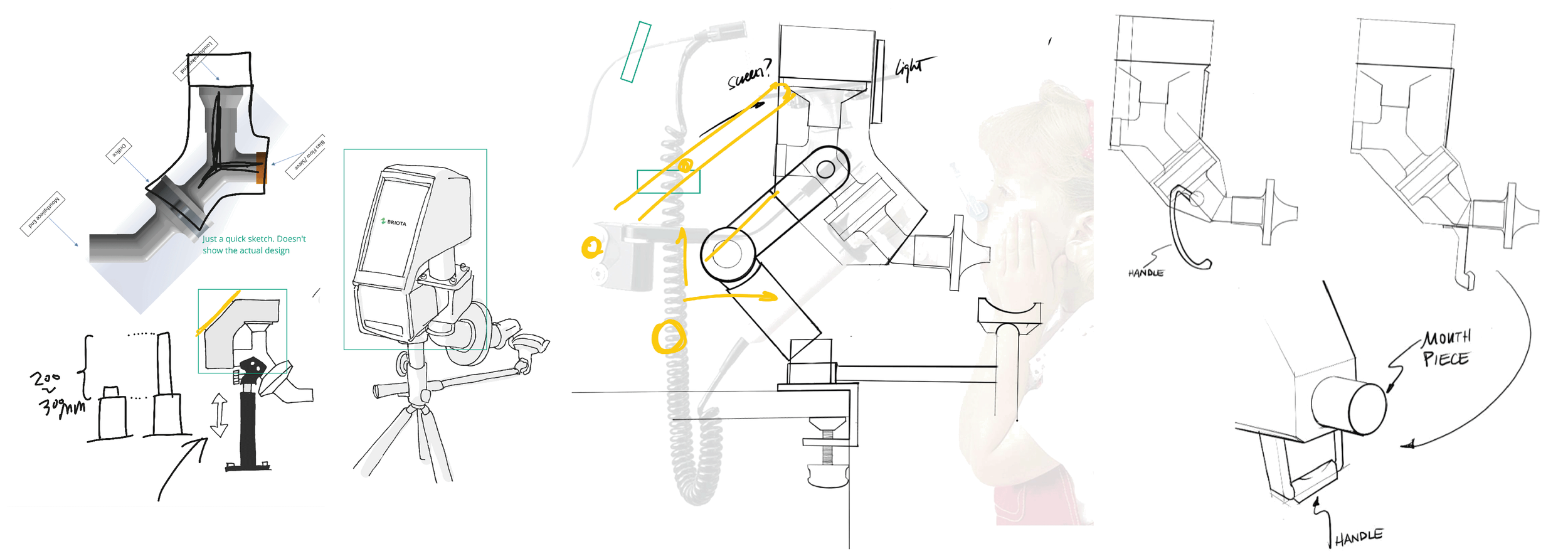

Concept Prototypes

From our sponsor, we learned that they want this device to be always mounted onto a stand with a screen (test progress and other features), handles for manipulating the device height, and integration with phone interface.

I explored the configuration of different features such as handle position; screen orientation; and use cases between doctors and patients (how they situate themselves around this device).

Water Kettle Design

Dentist Handle Design

Ear Design

Integrated Model

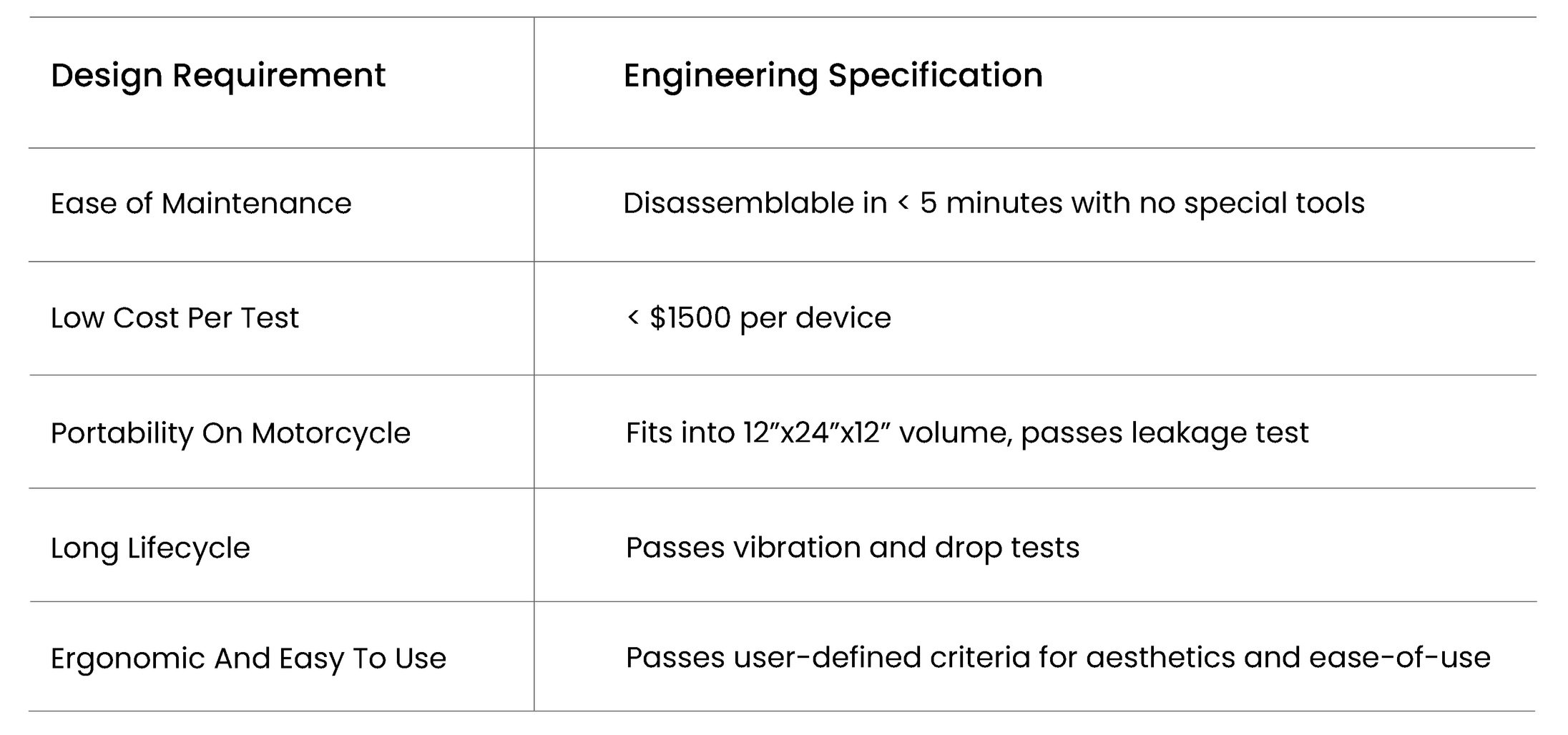

After some preliminary testing among the internal team, we found that symmetrical side handles, front screen and one-degree of freedom stand are most accommodating to various user scenarios.

User Test

I designed a set of UI that simulated the user flow of existing oscillmetry devices. The UI was printed and attached onto the device that instructs the users to interact with different parts of the device while performing a complete testing procedure.

User Test Findings

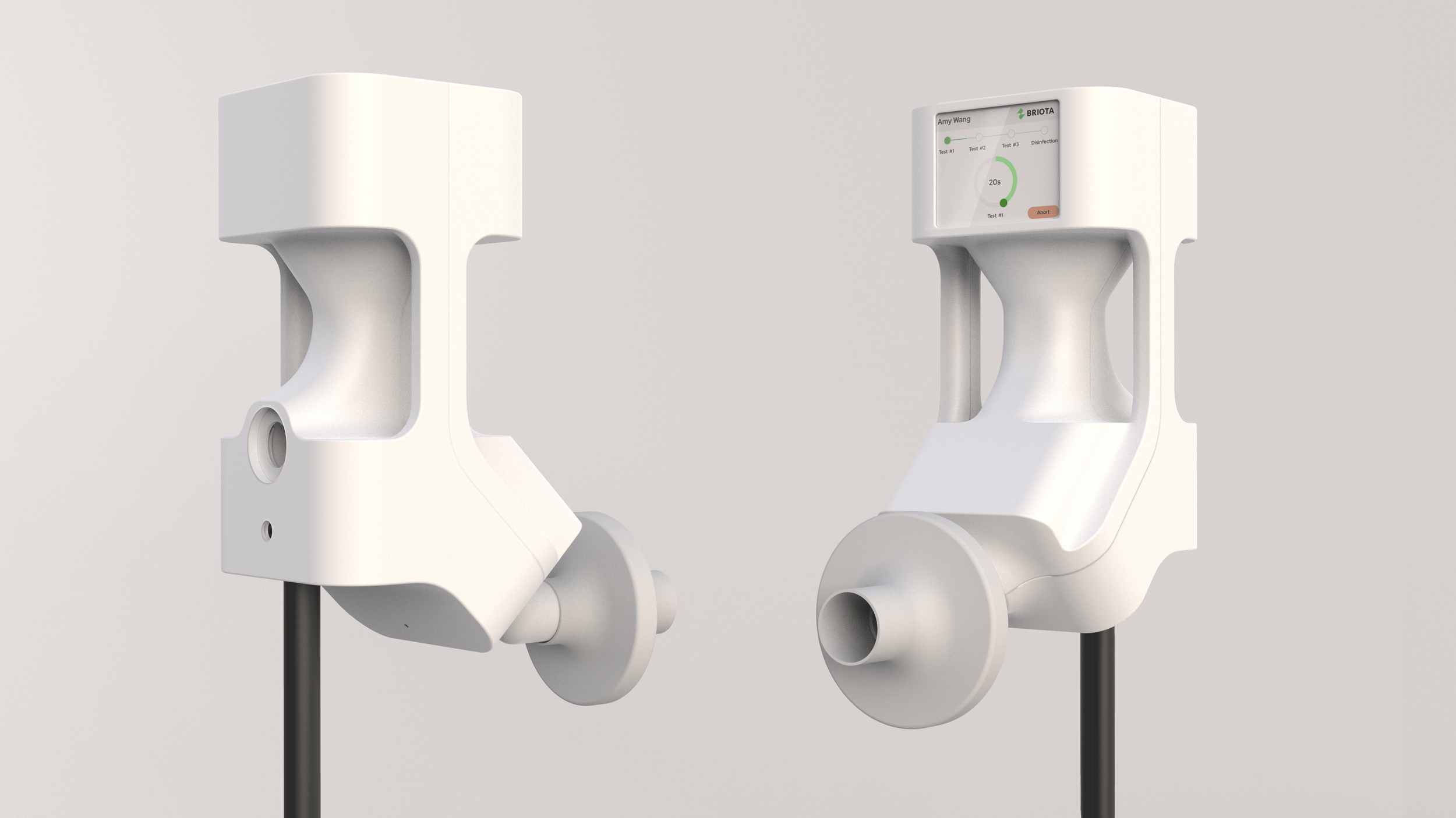

Final Design

We propose two designs for Briota IoSPRO based on our ergonomic and manufacturability investigations. A design with integrated handle and a design with off-the-shelf handle.

Design 1: Integrated Handle

Set up the device and adjust height

Set up test from screen

Begin Test

Exploded View

Due to the integrated handle feature, the design is split horizontally for two-part injection molding.

Design 2: Off-The Shelf Handle

To reduce the complexity of the mold for the integrated handle design (would likely require side pulls), we also proposed a second option that utilizes off the shelf handle.

With the off-the shelf handles, the injection mold is much more simplified. We split the model along the center line with screws clamping the two parts together.

Seal Design

The exterior housing is designed with integrated seal tracks that allow quick assembly with standard gasket stocks.

Shell Structural Design

The housing has a consistent 2.5mm wall thickness. Bolts go through recessed holes in one half of the housing and into ribbed and tapped fastener holes in the other half. Larger ribs are added to the manifold to add structural support to the device.

Future Work

As Briota (our sponsor) finalize their decisions on electronics, we propose three suggestions on this current design.

Incorporate small o-rings onto the threaded portions of all nine of the bolts for full water-proofing

Communication with SAM Integration (Briota’s manufacturer) on their injection molding capabilities and corresponding costs

Modify two-part mold interfacing to hide gasket seal along the edge